Embodying the oldest and most traditional inspection mechanism is that of visual inspection and visual testing. By calling on conventional times, the visual inspection methodology brings about several characteristics of the inspection subject that may be an asset, or a piece of equipment, while looking out for any flaws. These significant aspects of the inspection’s assets are brought to the forefront, whether as defects, faults, errors, or just remedial testing. Typically, visual inspection encompasses the prospects of inspecting and scrutinizing the asset for any flaws by the naked eye. However, today all that is changing. Now, technology is replacing the inspector’s eye with automation, just as in every other field.

Innovation and technology are the new faces of advancement and progress for almost every industry. With the high-end capabilities that are a product of intelligent automation, the different and disparate techniques and solutions offered by technology are valuable. One such beneficial and reaping technology is drone technology. Drones and UAVs are witnessing rising opportunities for application in diverse lines of work. Owing to their swiftness and agility, these winged machines are a concise means of delivering culminating and valued results.

Visual Inspection

When it comes to the mechanism of visual inspection, traditional and conventional techniques do not encompass the scope anymore. This is because visual inspection requires more than what the conventional methods can offer. The visual inspection mechanism has been utilizing help from technology and innovation to keep up with these demands. In essence, drone technology adoption in this work line has helped overcome several challenges and shortcomings of inspection. Thus, UAVs have been employed in the booming fields of mining inspection, utility inspection, tower inspection, bridge inspection, and significantly more.

Critically, visual inspection demands a sharp and observant eye that cuts through the object, like a laser, to look for details. With the human eye, there are a fair number of limitations. The most optimal way to get speedy and accurate observational results is to adopt new ways, such as drones and UAVs. Unmanned Aerial Vehicles (UAVs) have been gaining popularity for their diverse operations and data acquisition. Diving into the significance of observation and data collection in visual inspection space helps us realize UAVs’ real importance in the same space. The abilities of drones to maneuver, move swiftly, and hover helps to collect precise data of the object of interest while thoroughly inspecting it for the details. Consequently, drones help save time, increase performance, reduce the cost of resources, and enhance efficiency.

Benefits of adopting drones for visual inspection

The abstraction of drones in place of the inspector’s eye is a buzzing subject of interest, owing to UAVs’ creativity and advancement. Drone inspection has paved the way for convenient and swift mapping and surveying, these being the key focus of inspection. While understanding aerial inspection’s intrinsicality, the creativity to adopt drones for industrial inspection has pulled off the possibilities of advanced techniques and growing progress. UAVs, also referred to as quadcopters, come in varied shapes and sizes that favor the different purposes of inspection, whether it is wind turbine inspection, oil and gas inspection, or even inspection of construction sites. Having mentioned this, drones boast of immense advantages and benefits that result in an augmented quality of aerial inspection services.

Thorough Inspection

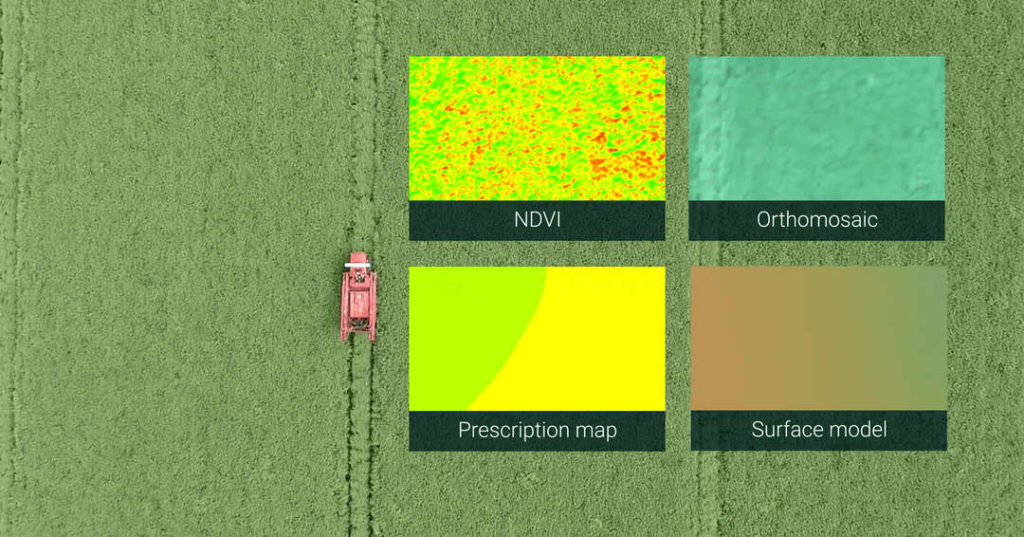

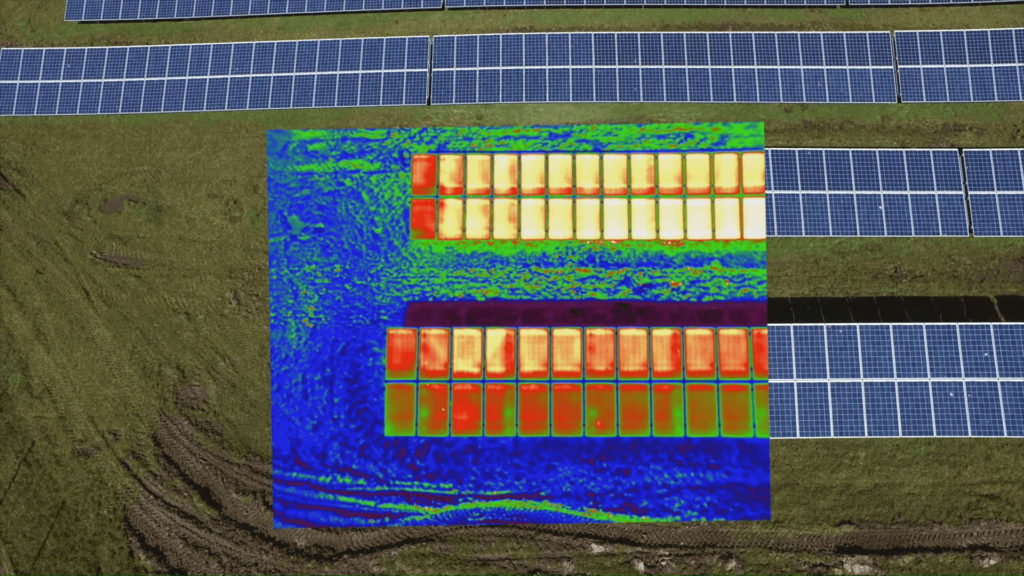

Upgrading to use technological marvels such as drones and UAVs in the sphere of visual inspection has proven to be highly respected. UAV inspection leads to undeniable perks and gains, including the convenience of performing operations. Most importantly, drones travel through the object or asset of interest to perform a thorough inspection and entail the object’s details. The multispectral sensors help focus on the essential aspects and look for defects, faults, or flaws. Multiple checks for the thorough inspection of the same asset can be eliminated with drones’ adoption for industrial inspection.

Accurate Results

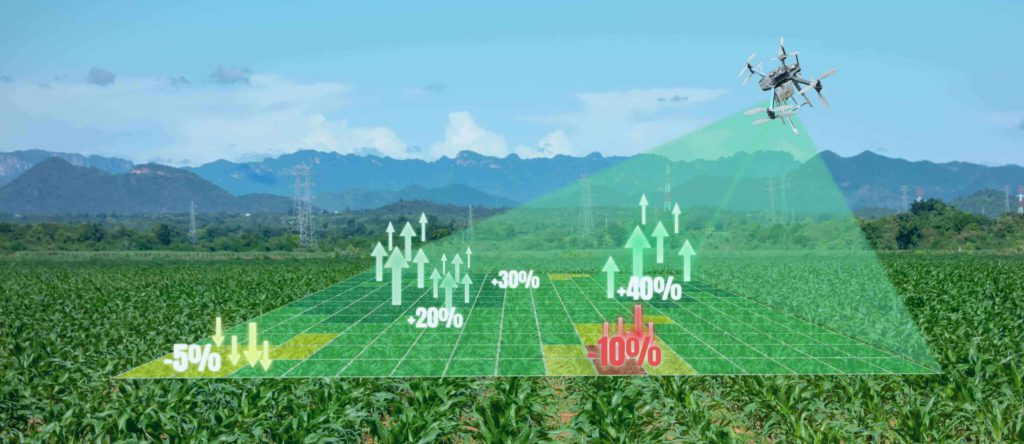

The prodigious nature of drones brought about by their numerous features has actively used quadcopters for aerial inspection services. The innovation of Unmanned Aerial Vehicles, UAVs, to be applied in visual inspection entails rewarding outcomes that further uplift the industry. Skimming through the asset of interest to collect and obtain the results has been challenging regarding construction sites, agricultural farmlands, oil mines, power transmission lines, and marine environments due to these assets’ enormity. This being said, the ability to acquire perfectly calculated results, and measurements, was long overshadowed. Nevertheless, the onset of aerial and drone inspection has allowed accurate results to be effectively delivered.

Time-critical Inspection Operations

The prodigious nature of drones brought about by their numerous features has actively used quadcopters for aerial inspection services. The innovation of Unmanned Aerial Vehicles, UAVs, to be applied in visual inspection entails rewarding outcomes that further uplift the industry. Skimming through the asset of interest to collect and obtain the results has been challenging regarding construction sites, agricultural farmlands, oil mines, power transmission lines, and marine environments due to these assets’ enormity. This being said, the ability to acquire perfectly calculated results, and measurements, was long overshadowed. Nevertheless, the onset of aerial and drone inspection has allowed accurate results to be effectively delivered.