Solar Energy

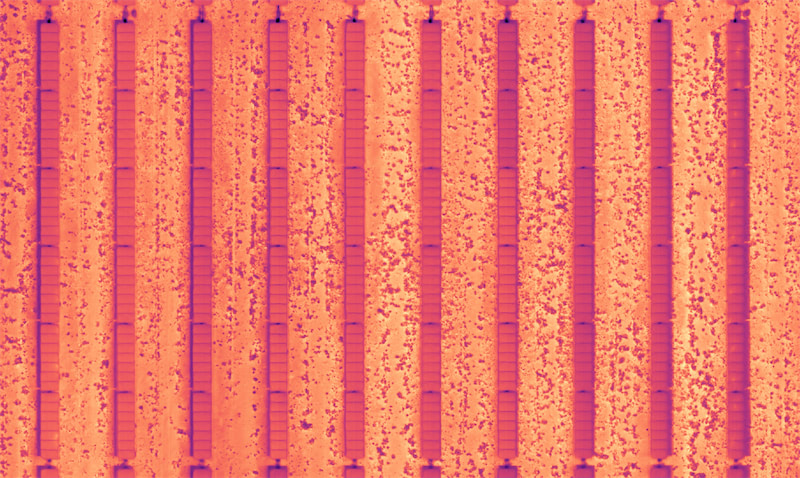

With a passion for technology and drive to assist various industries, the renewable energy sector is flourishing with Drone Surveys. It is imperative to secure the quality of the solar power plant for adequate power generation, saving costs, and to maintain a long life of the asset. We offer timely thermal imaging (Aerial Solar) Inspections for Solar Power Plants to guarantee the safety and effective deployment of these solar systems.

Our fundamental purpose of using Thermal Mapping is to recognize any fault or damage in the solar panels and for the owners to be able to request for warranty/replacement from manufacturers. Our failure-free operations that have adopted cutting-edge UAV technology ensure reliability, affordability, and utmost accuracy. Our trained drone pilots use premium drones with thermal sensors for Aerial Inspection while maintaining safety in solar farms. Drone Surveys and UAV Inspections produce superior quality data for detailed solar panel analysis.

Through Drone Surveys and Thermal Mapping of solar power plants, we recover essential information. Precise solar farm Inspection can spot cell defects, cell failure, dirt on Photovoltaic cells, Interconnection failure, Degradation of solar cells, Decrease of operational efficiency, etc. Humans cannot implement Thermal Mapping and Aerial Infrared imaging alone. The industry needs to depend on cutting-edge UAV technology for solar farm Inspection, Monitoring, and large-scale maintenance. Our deliverables include geotagged high-resolution drone images and orthomosaics for quick decision-making. We have offered solar farm inspection services to more than 100 solar farms, and have assisted them continuously in procuring a higher return on investment.

Wind Energy

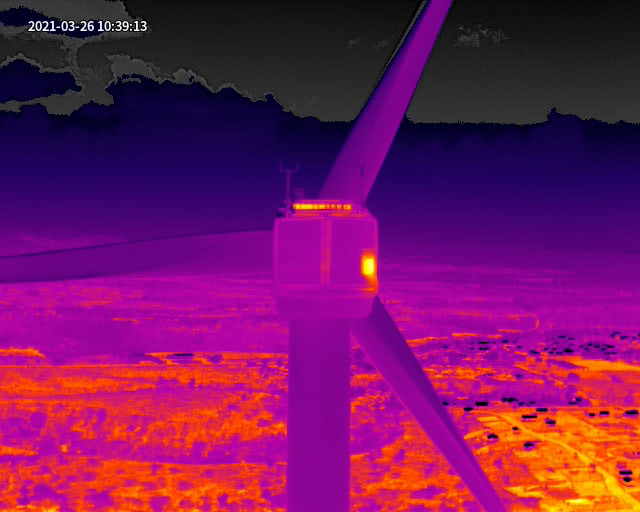

Wind turbine and blade inspection is very challenging as the internal structure of the blade may develop some structural problem that may be invisible from outside. We offer drone powered solutions to tackle such challenges. Our Drones are equipped with highly advanced sensors like thermal, infrared sensors specially designed and calibrated for wind Turbine and Blade inspection that gathers information (data) rapidly and can see up to 15cm deep into wind turbines. Our team uses machine learning and advanced processing softwares to find any internal or external structural issues (issues as small as 5mm) and help the wind farms to ensure structural integrity, extend lifespan of turbines and take required action at the right time.

Our Pilots are highly trained and they maintain all the safety standards while doing aerial inspection of wind turbines and blades and we have zero accident record throughout any survey or inspection mission. So far we have already covered Inspection of 200+ Turbines and helped wind farms to maximize efficiency and reduce downtime.

Transmissions Lines

Coatzadrone provide drone-powered solutions for Transmissions Lines and Cooling Towers, etc. Over the preceding few years, our Survey Drone Service has collected inspection data from sizable utility poles and towers across Mexico and Latin America. Prioritizing quality and efficiency, we utilize drones outfitted with thermal and infrared sensors for Aerial Inspection. Our drone pilots have been trained explicitly for powerline and cooling tower inspections, making them a significant provider source for our success.

Survey drone services assisted with Thermal Imaging Sensors allow a more in-depth and comprehensive evaluation of such utilities. It has a plethora of benefits, including restored safety, diminished downtime, refined data output, increased operational efficiency, etc. The maximum advantage of, for example, tower inspection through drones would be fewer costs. This is because the technology is more affordable when compared to an on-ground crew for the same assessment.

We offer Powerline Inspection services utilizing thermal imaging techniques to achieve engineering-grade levels of precision. We also submit geotagged data obtained through aerial inspection for a swift decision-making process. Through intense powerline inspection, we can successfully recognize the following:

- Tower Concrete basement defects

- Insulator Overheating

- Wire Overheating

- Wire Breaks

- Tower Mechanical Defects

- Wire Slag Estimation

- Installation Check

- Birds Nest

- Antenna

- Weather Damage

- Metal Rust

- Equipment Check

- Missing Components (such as bolts)

- Guyed Wire Quality

- Electric Wire Joints or Wire Break

- Cracks

Our Powerline / Transmission Lines Inspection drones furnished with ferro-magnetic protection allow us to carry inspections and fly in close perimeter to the powerline securely. An excellent alternative to traditional methods is that this survey drone service reduces costs by 30-50%, safeguards personnel, and contributes more valuable output.